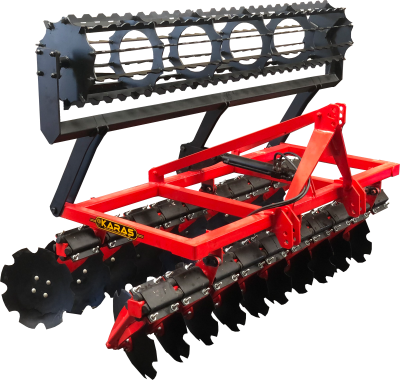

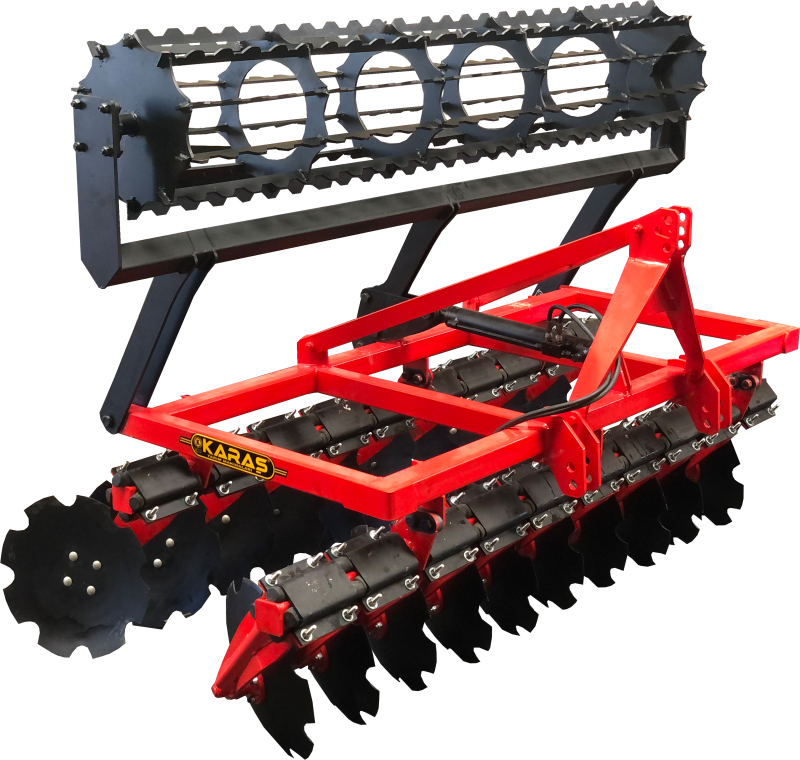

Lıght type Compact Discharrow (H034)

Compact disc harrow performs breaking and mixing procedures more efficiently than disc harrows known due to the independent disc structure and machine construction; and each disc operates individually due to the bearing. When rubber cushions which are on each disc are stuck on an obstacle, breaking and damages on the chassis are removed because of forward-backward movements of the disc. It is effected less from the surface roughness of the field. It almost gives no harm to the field leveling. Furthermore, the roll installed on the chassis steps on the soil lifted by the discs at the same time and minimizes the humidity loss after the operation. The machine may be operated in heavy soils easily.

| SPECIFICATIONS | UNIT OF MEASUREMENT | BHKG-16 | BHKG-18 | BHKG-20 | BHKG-24 | BHKG-28 | |

|

DISC NUMBER | PCS | 16 | 18 | 20 | 24 | 28 |

|

DISC DIAMETER | mm | 510x4,5 | 510x4,5 | 510x4,5 | 510x4,5 | 510x4,5 |

|

DISTANCE BETWEEN DISC |

cm | 25 | 25 | 25 | 25 | 25 |

|

WORKING WIDTH | cm | 200 | 225 | 250 | 300 | 350 |

|

WORKING DEPTH | cm | 10 | 10 | 10 | 10 | 10 |

|

WEIGHT | kg | 800 | 840 | 905 | 1020 | 1250 |

|

POWER | HP | 70-80 | 75-90 | 85-105 | 100-115 |

105-125 |